Lever fillers

In the previous article about sac fillers I described Crescent fillers,

Sleeve fillers , Coin fillers and Twist

fillers. This article covers the Lever fillers, Hatchet fillers and button

fillers.

I would like to thank Len Provisor for reviewing and editing this article.

Lever fillers:

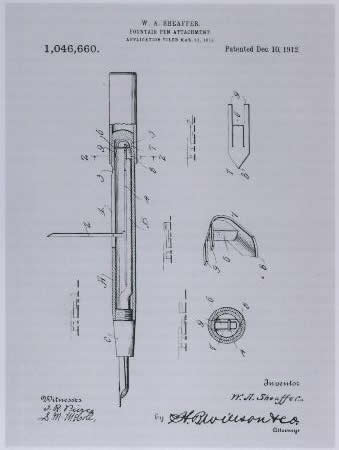

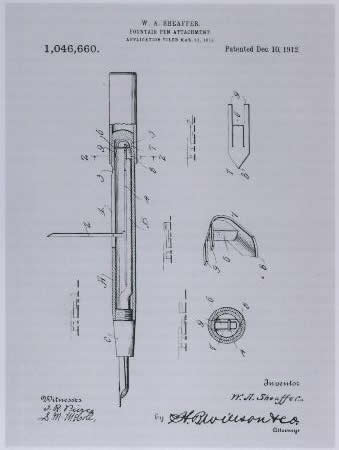

Walter A. Sheaffer (a jeweler from Fort Madison Iowa) designed the lever filler

and patented it in 1908. Sheaffer wanted to improve the odd looking and grip

spoiling Conklin crescent filler. His patent included a lever that was fitted

in a shallow recess in the barrel. The lever was attached to the barrel by a

hinge. This allowed the lever to be flipped to a 90 degree angle to the barrel,

thus lowering a pressure bar inside the barrel, which compressed the sac. Returning

the lever back to it’s place allowed the sac to inflate and draw in ink.

Here is Sheaffer improved patent from 1912.

Sheaffer began producing it’s first lever fillers in 1912, and this

efficient and elegant filling system was soon adopted by many manufacturers

becoming an almost industry standard.

Accidents were avoided by a good fit of the lever to the barrel first due to

the expansion of the sac itself and later due to sprung pressure bars that pushed

the lever upwards keeping it firmly closed. Other various patents to keep the

lever in place included the Hatchet filler (described in this article) and Conway

Stewart early “flanges” (two little metal rods placed on both sides

of the lever) that friction kept the lever in place.

The picture is of an early unnumbered Duro Big Red flanged lever filler (The

pen is part of Jonathan Donahaye Conway Stewart collection)

Many companies adopted the lever filling system abandoning others. One of

these companies was Waterman, which introduced its first lever filler in 1915

thus abandoning the previous pump, coin and sleeve fillers. Waterman’s

lever filler is different from Sheaffer’s in that the lever is placed

inside a metal box and the lever hinges to the box instead to the barrel directly.

Here is a picture showing the two different levers: the Sheaffer in green and

the brown Waterman. One can easily spot the hinge hole in the Sheaffers barrel

near the lever :

And here are the pens: 1924 Jade Radite Sheaffer Lifetime and a later mahogany

Waterman 94 from the 30’s:

Lever fillers were widely used by many companies in the US, Europe and Japan

(although German companies were quick to adopt the piston filler almost abandoning

all other filling methods).

Here is a picture of various lever fillers from different manufacturers: L to

R – French Meteore 327, French Gold Starry, UK Swan minor 1, UK Conway

Stewart 286, Sheaffer combo, MHR Edison, Wahl Doric, Wahl Skyline, Morton, Sheaffer

Oversize Balance, Waterman 0555,

Le Boeuf, Aikin Lambert, Conklin Ensemble combo.

Hatchet fillers:

The hatchet fillers were one of the ways companies devised in order to “bypass”

Sheaffer’s patent on the lever filler. Hatchet fillers were used by John

Holland and by Crocker (though both are named hatchet fillers they do not have

the same mechanism).

Crocker Hatchet filler:

Here is a BCHR Crocker hatchet filler from the early 1910’s:

From a first glance one might think this is a lever filler …. But:

The lever is attached to a blind cap that screws into the barrel. This way

the “lever” is secured - it won’t open by accident. The Crocker

company produced blow fillers and hatchet fillers from 1902 to 1931, but the

important fact about this company is that it’s owner Seth. S. Crocker

started the Chilton Company in 1923 which produced the high quality pneumatic

fillers.

John Holland Hatchet filler:

Here is a John Holland hatchet filler (produced 1908 – 1912):

The “lever” in this pen is not really a lever. This patent is

a combination between the lever filler and the crescent filler. The hatchet

is flipped open (it has a hinge like the lever fillers) until it stops flat

on the opposite side; there is lies “back to back” to the pressure

bar inside the barrel. But now the protrusion that was inside the barrel sticks

out of the barrel and pressing it causes the depression of the pressure bar.

After the filling procedure is over the hatchet is returned to the original

position.

Button fillers:

During the 1910’s, Geo. S. Parker started producing Parker second attempt

of self-filling pens (the first attempt was in 1905 with a strange and unsuccessful

two hump filler that competed poorly with Conklin’s patent) – the

button filler.

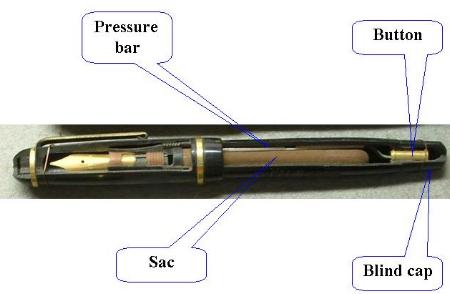

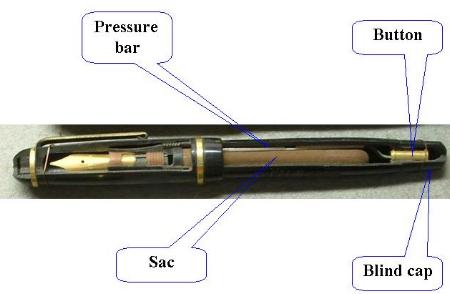

This type of filler has a pressure bar inside the barrel. One of the pressure

bar end rests against the section, while the other rests against a button at

the end of the barrel. Pressing the button causes the pressure bar to curve

inside the barrel thus compressing the sac. Usually one has to press the button

several times in order to fill the sac. Accidents are avoided by a blind cap

that screws on covering the button.

The button filler advantages are that the barrel can retain its original shape

without any “additions” (such as sleeves, crescents, levers, hatchets)

or openings (coin fillers, matchstick fillers) in the barrel. Leaking in these

pens, due to sac deterioration is less prone to cause a mess because of the

blind cap, than in lever fillers.

Here is an image of a cut out button demonstrator of a 1950’s East German

Garant Silka fountain pen. Following is a picture of the entire demonstrator

display of this fountain pen showing all parts used to assemble this pen.

Parker used the button filler for a long period in the Jack-knife,

Duofold (original and the 40’s) , Thrift time, Challenger models. The

button fillers were produced beside the Vacumatic and even the 51 models.

Here are 3 Parker button fillers - L to R: Lapis flattop Duofold Sr. (1928),

red Permanite Streamlined Jr. (1930’s), Thrift time mahogany with white/blue

streaks (1932 – 1936).

Many other companies used the button filler method. Here is one more example

of button fillers from Penol (Denmark):

The Penol Company (which stands for Pen Olsen) was founded

in Denmark by Christian Olsen. Christian received the distribution rights for

Parker in Denmark, Sweden and Norway in 1905. In 1932 a factory was opened and

licensed Parker together with Penol pens were produced. It was only natural

that Penol used the button filling system in their pens. Production of fountain

pens stopped in 1966, but the Olsen Company still represents Parker and distributes

Parker products in Scandinavia.

Here is a picture of 3 Penol button fillers – L to R: coral red de Luxe

BO aero (1935), green/black marbled Ambassador 5 (1947), black Ambassador Sr.

(1946).

The aero Penols have an interesting feature: an ink window like a piston filler,

but …

with a button filler mechanism. This is achieved by a transparent part that

is attached to the section on one side and to the sac on the other. This transparent

elongation of the section allows the in level to be checked like in piston fillers.

Here is the Penol aero with its internal parts exposed:

The Camel Pen Company produced in 1935 a special button filler

that was somewhat different. The pen utilized a pressure bar and a button, but

the sac was open on both sides, one side attached to the section and the other

to an ink chamber near the other end of the barrel. The button in this pen contained

ink pellets, and the pen was filled with water, so no ink pot was needed. The

ink pellet and water mixed in the ink chamber enabling the pen to write with

ink. When the ink pellets were exhausted one had only to screw in a new button

(with ink pellets. The Camel Pen Company survived only for 3 years.

Here is a Camel fountain pen with the special button exposed:

|